A different beginning creates a different outcome.

A different beginning creates

a different outcome.

A different beginning creates a different outcome.

A different beginning creates a different outcome.

From start to finish,

we design every step of the technology.

From start to finish,

we design every step of the technology.

From start to finish,

we design every step of the technology.

From start to finish,

we design every step of the technology.

Technology built into

every core process —

a difference proven by results.

Technology built into

every core process —

a difference proven by results.

From developing ceramic materials and blending powders,

to firing at 1,300°C, precision machining, modularization, and final assembly.

Every step of the technology that touches your skin is designed

and created from start to finish.

Unseen precision is what builds trust in every experience.

From developing ceramic materials and blending powders,

to firing at 1,300°C, precision machining, modularization, and final assembly.

Every step of the technology that touches your skin is designed

and created from start to finish.

Unseen precision is what builds trust in every experience.

Technology built into

every core process —

a difference proven by results.

From developing ceramic materials and blending powders, to firing at 1,300°C, precision machining, modularization, and final assembly.

Every step of the technology that touches your skin is designed and created from start to finish.

Unseen precision is what builds trust in every experience.

Technology built into

every core process —

a difference proven by results.

From developing ceramic materials and blending powders,

to firing at 1,300°C, precision machining, modularization, and final assembly.

Every step of the technology that touches your skin is designed

and created from start to finish.

Unseen precision is what builds trust in every experience.

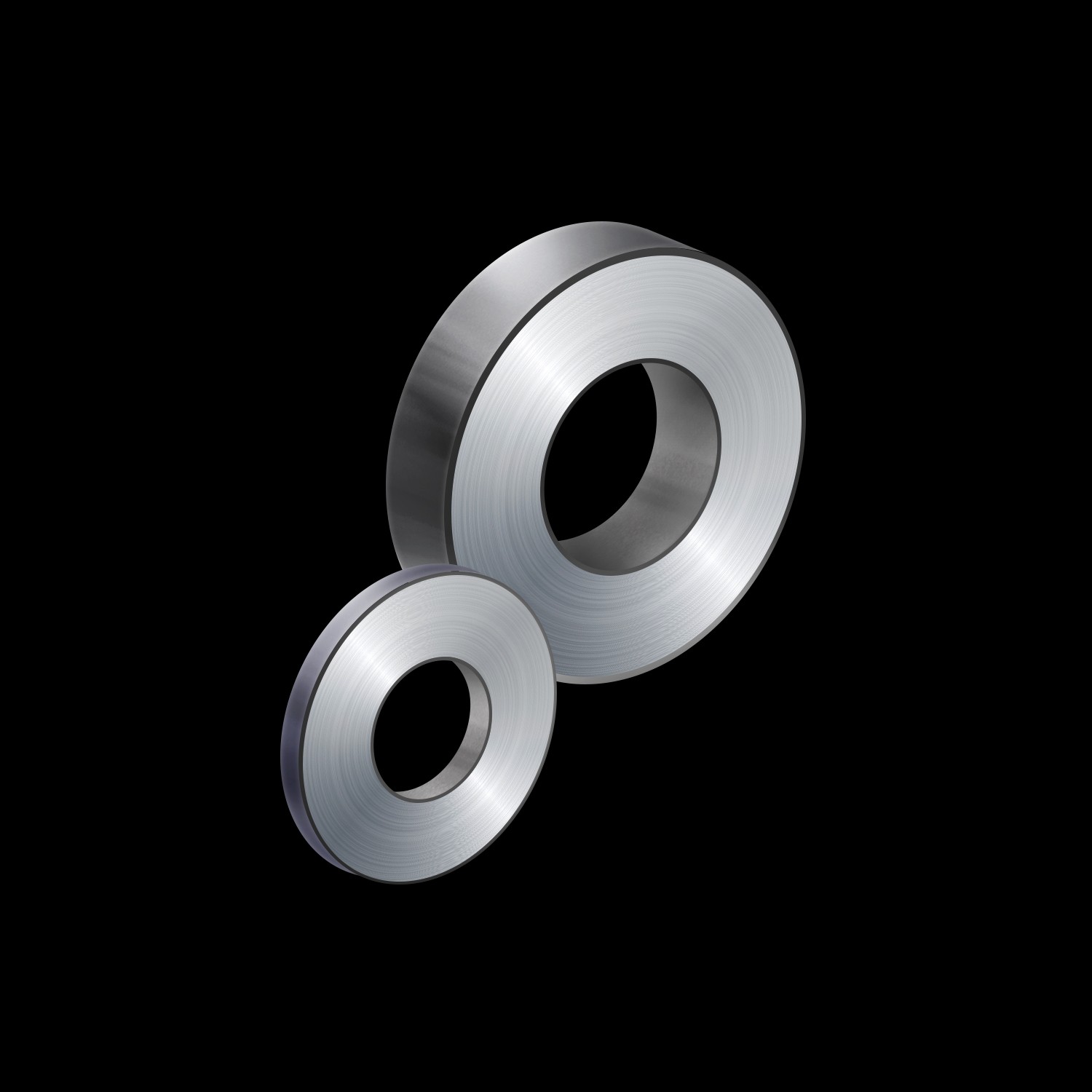

Piezo Ceramics

PZT

Piezoelectric Ceramic (PZT) is a functional material that transforms mechanical pressure

into electrical signals, and electrical signals into precise vibrational energy.

At Eco DM Lab, we develop high-sensitivity, high-durability piezoelectric ceramics

to deliver solutions across medical devices, precision machinery, and sensor systems.

Engineered for miniaturization, silent performance, and precise control,

this material is recognized as a core component shaping the industries of the future.

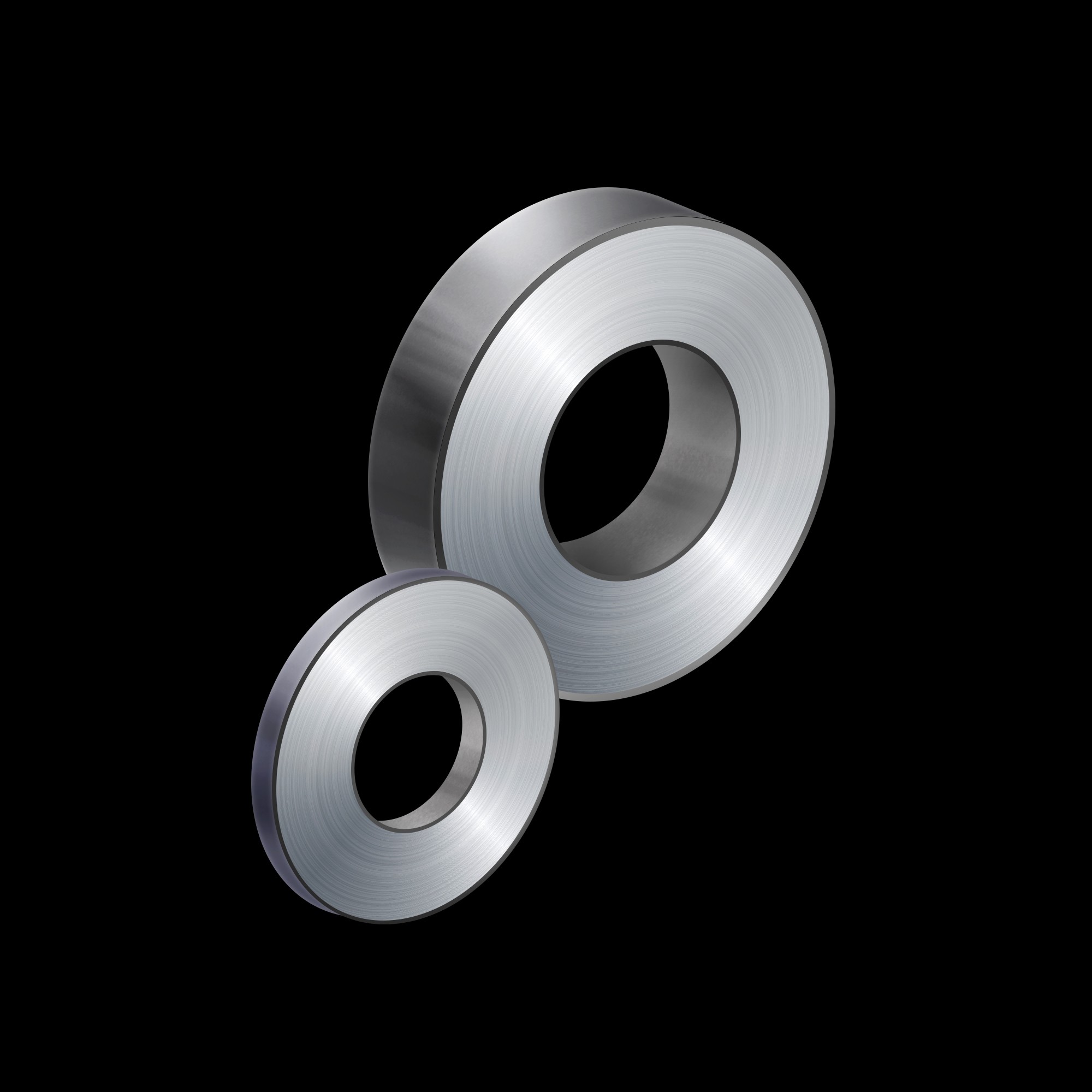

1MHz

Thickness : 2.1mm Outer Diameter (OD) : 34mm

Inner Diameter (ID): 14.8 mm

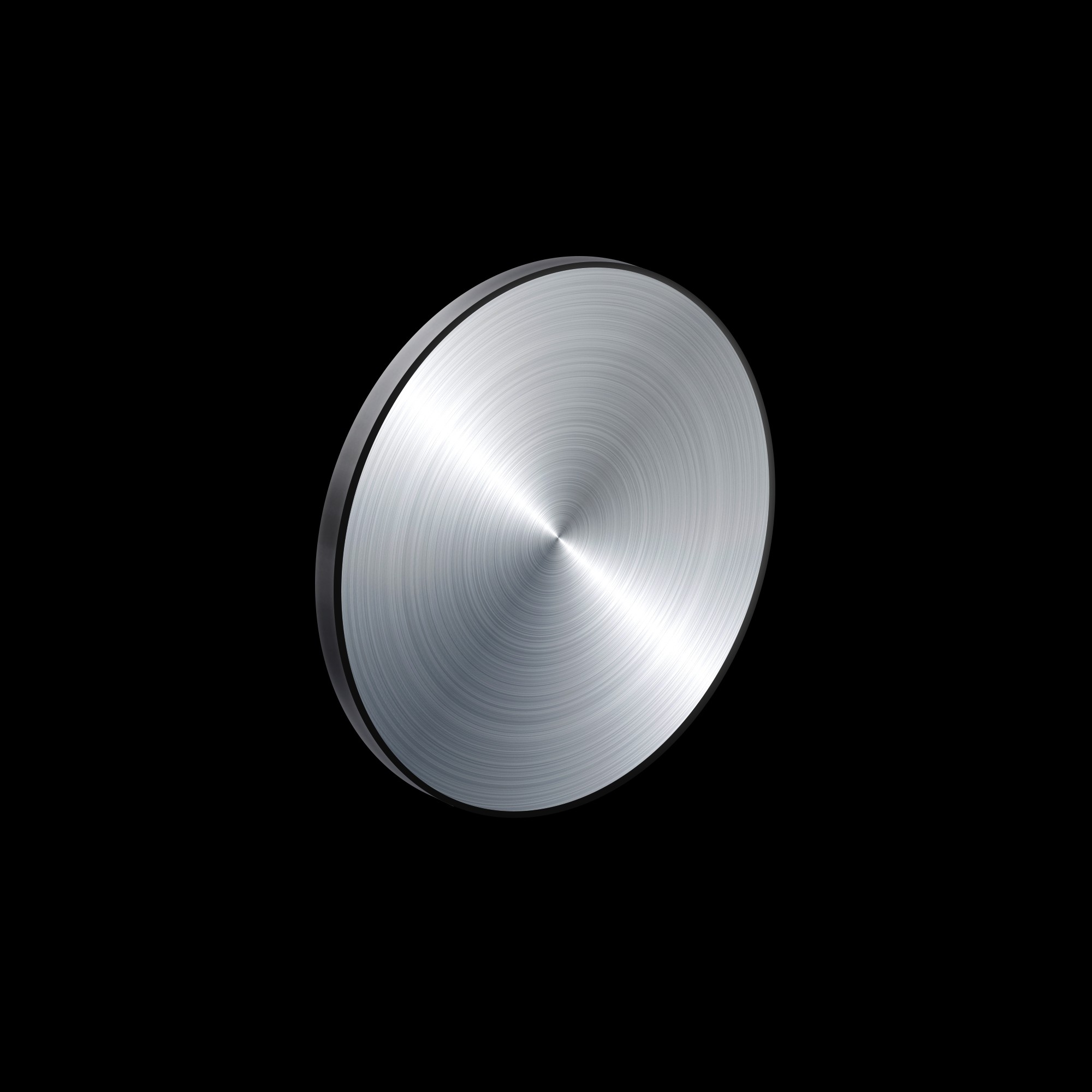

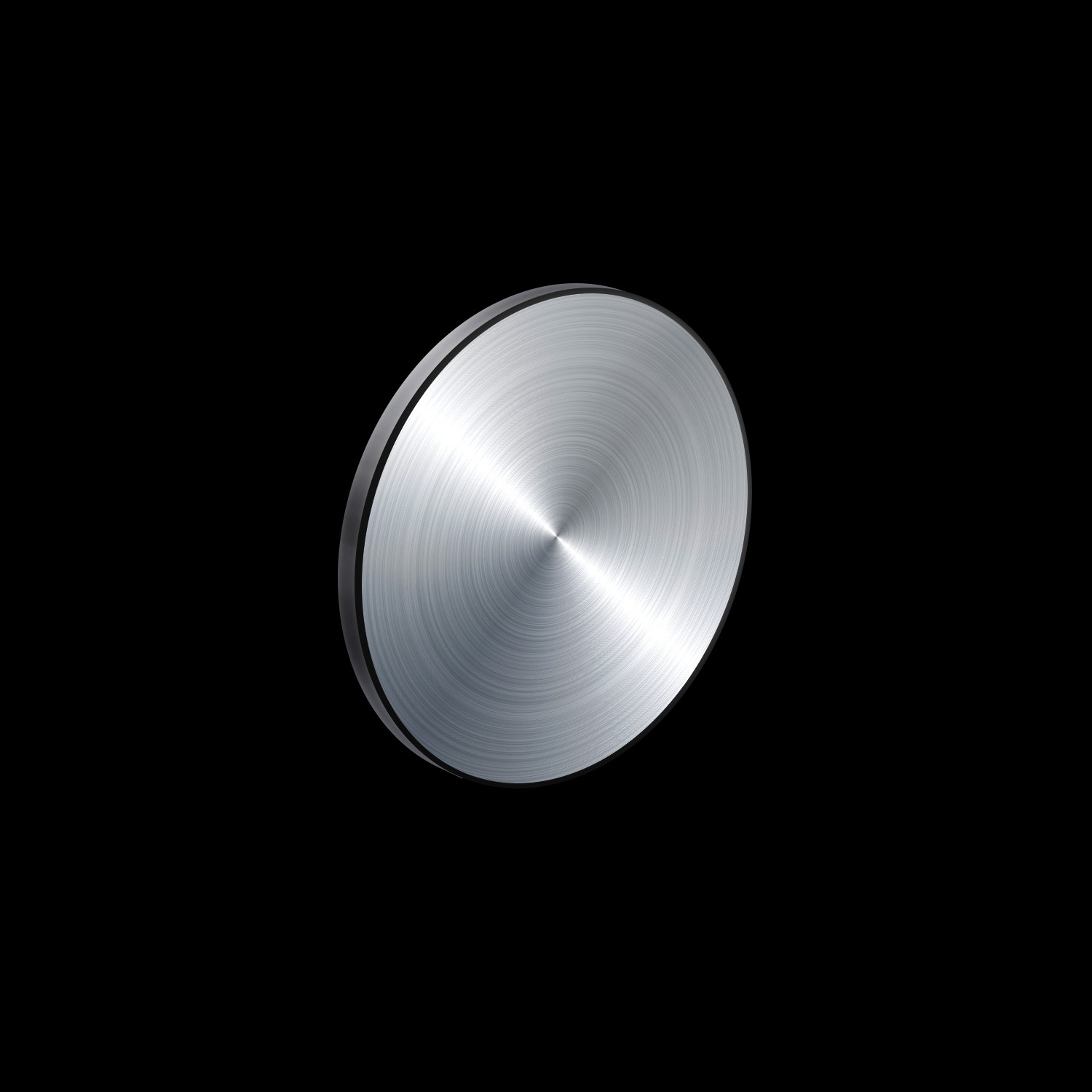

3MHz

Thickness : 0.7mm Diameter : 12mm

Product Line

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

Fields of application

Performance indicators

Functions

Advantages

High dielectric constant (k)

Electrical storage capacity

Improved sensitivity and precision

High mechanical q value

Vibration quality retention

High-frequency precision diagnostics enabled

High d₃₃ value

Vibration-to-electric conversion efficiency

Implementation of high-sensitivity sensors

High curie temperature

High-temperature operating stability

Enhanced adaptability to industrial and medical environments

Low tanδ (loss factor)

Energy loss minimization

Reduced heat generation for long-duration operation

Core technological competence

Custom design flexibility

Optimized for medical, precision machinery, and smart devices with diverse form and structural design options

Uniform microstructure

(1–2 μm particles)

Superior mechanical strength and durability for the production of high-reliability products

High q characteristics

(high quality factor)

Excellent resistance to thermal variation during extended use ensures stable operation without performance loss

High Kp

(high coupling coefficient)

Superior electro-mechanical energy conversion efficiency that maximizes sensor and actuator performance

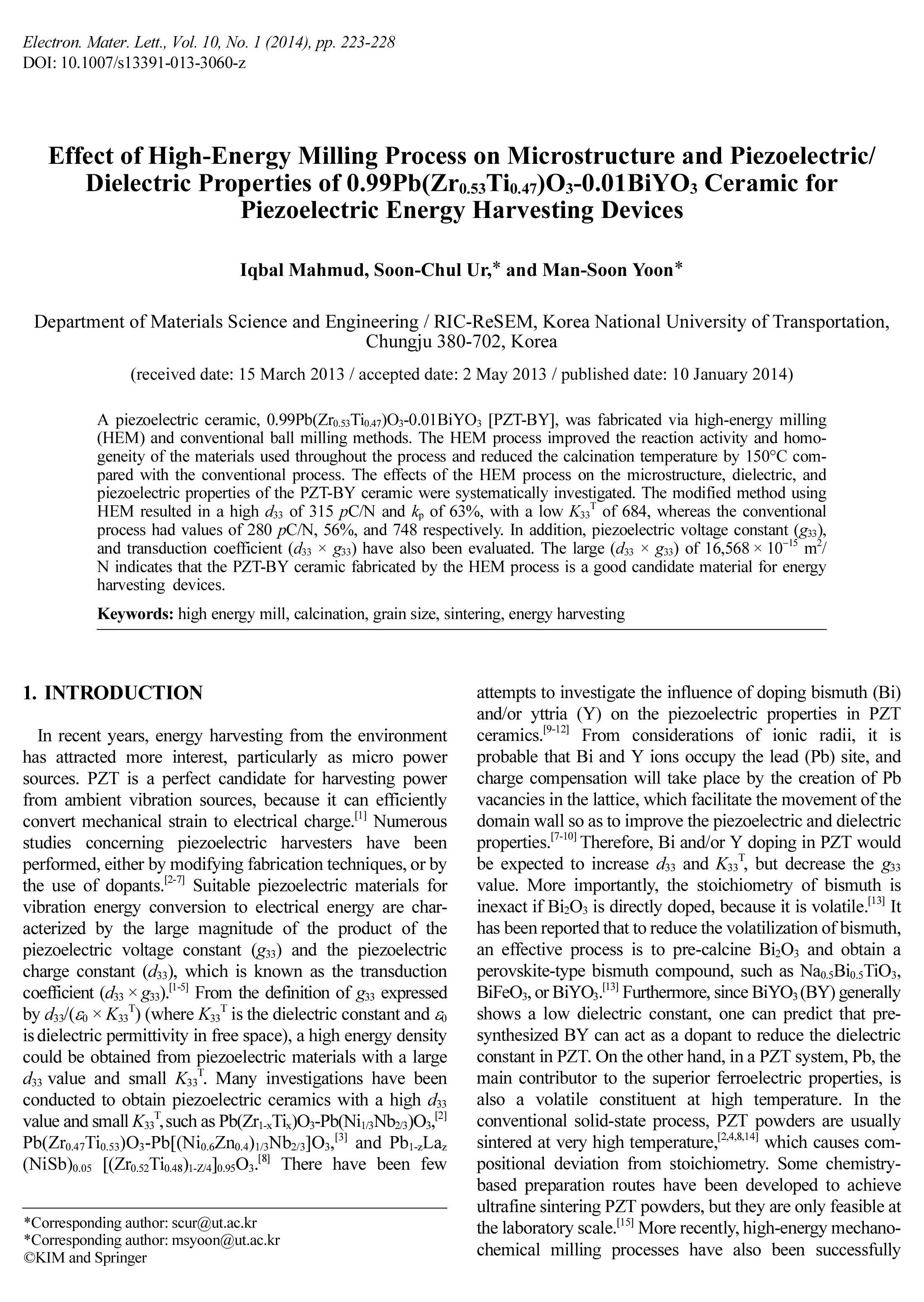

Patents and publications

Piezoelectric materials of (1-x)Pb(Zr0.53Ti0.47)O3–xBi(Y0.7Fe0.3)O3 for energy-harvesting devices

Microelectronic Engineering 126 (2014) 71–78

Piezo actuator having an electrode structure for a torsional vibration mode, and rotation-type ultrasonic motor including same

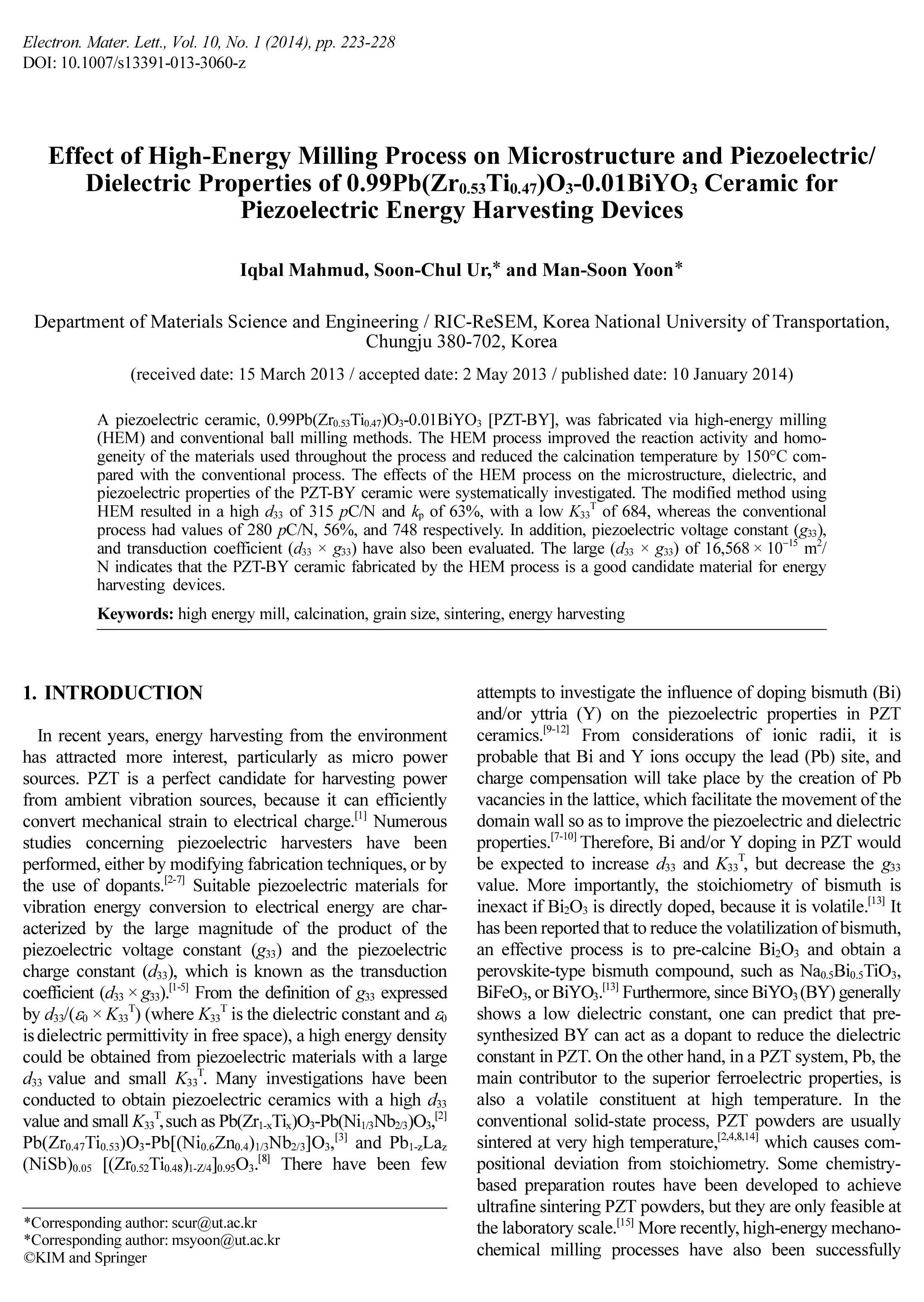

Electron. Mater. Lett., Vol. 10, No. 1 (2014), pp. 223-228

Piezo Ceramics

PZT

Piezoelectric Ceramic (PZT) is a functional material that transforms mechanical pressure

into electrical signals, and electrical signals into precise vibrational energy.

At Eco DM Lab, we develop high-sensitivity, high-durability piezoelectric ceramics

to deliver solutions across medical devices, precision machinery, and sensor systems.

Engineered for miniaturization, silent performance, and precise control, this material is recognized as a core component shaping the industries of the future.

1MHz

Thickness : 2.1mm

Outer Diameter (OD) : 34mm

Inner Diameter (ID): 14.8 mm

3MHz

Thickness : 0.7mm Diameter : 12mm

Product Line

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

Fields of application

Performance indicators

Functions

Advantages

High dielectric constant (k)

Electrical storage capacity

Improved sensitivity and precision

High mechanical q value

Vibration quality retention

High-frequency precision diagnostics enabled

High d₃₃ value

Vibration-to-electric conversion efficiency

Implementation of high-sensitivity sensors

High curie temperature

High-temperature operating stability

Enhanced adaptability to industrial and medical environments

Low tanδ (loss factor)

Energy loss minimization

Reduced heat generation for long-duration operation

Core technological competence

Custom design flexibility

Optimized for medical, precision machinery, and smart devices with diverse form and structural design options

Uniform microstructure

(1–2 μm particles)

Superior mechanical strength and durability for the production of high-reliability products

High q characteristics

(high quality factor)

Excellent resistance to thermal variation during extended use ensures stable operation without performance loss

High Kp

(high coupling coefficient)

Superior electro-mechanical energy conversion efficiency that maximizes sensor and actuator performance

Patents and publications

Piezoelectric materials of (1-x)Pb(Zr0.53Ti0.47)O3–xBi(Y0.7Fe0.3)O3 for energy-harvesting devices

Microelectronic Engineering 126 (2014) 71–78

Piezo actuator having an electrode structure for a torsional vibration mode, and rotation-type ultrasonic motor including same

Electron. Mater. Lett., Vol. 10, No. 1 (2014), pp. 223-228

Piezo Ceramics

PZT

Piezoelectric Ceramic (PZT) is a functional material that transforms mechanical pressure

into electrical signals, and electrical signals into precise vibrational energy.

At Eco DM Lab, we develop high-sensitivity, high-durability piezoelectric ceramics

to deliver solutions across medical devices, precision machinery, and sensor systems.

Engineered for miniaturization, silent performance, and precise control,

this material is recognized as a core component shaping the industries of the future.

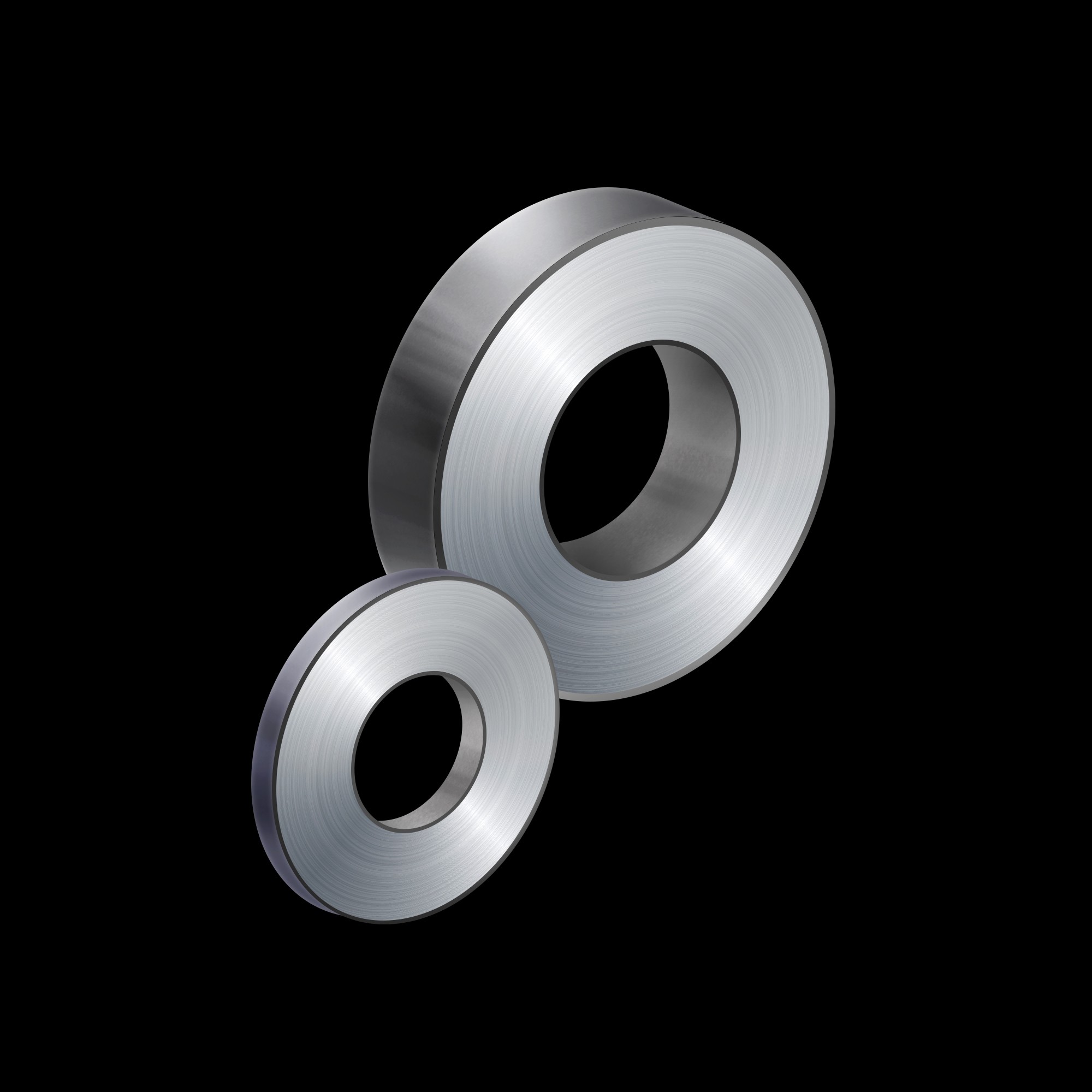

1MHz

Thickness : 2.1mm Outer Diameter (OD) : 34mm

Inner Diameter (ID): 14.8 mm

3MHz

Thickness : 0.7mm Diameter : 12mm

Product Line

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

Fields of application

Performance indicators

Functions

Advantages

High dielectric constant (k)

Electrical storage capacity

Improved sensitivity and precision

High mechanical q value

Vibration quality retention

High-frequency precision diagnostics enabled

High d₃₃ value

Vibration-to-electric conversion efficiency

Implementation of high-sensitivity sensors

High curie temperature

High-temperature operating stability

Enhanced adaptability to industrial and medical environments

Low tanδ (loss factor)

Energy loss minimization

Reduced heat generation for long-duration operation

Core technological competence

Custom design flexibility

Optimized for medical, precision machinery, and smart devices with diverse form and structural design options

Uniform microstructure

(1–2 μm particles)

Superior mechanical strength and durability for the production of high-reliability products

High q characteristics

(high quality factor)

Excellent resistance to thermal variation during extended use ensures stable operation without performance loss

High Kp

(high coupling coefficient)

Superior electro-mechanical energy conversion efficiency that maximizes sensor and actuator performance

Patents and publications

Piezoelectric materials of (1-x)Pb(Zr0.53Ti0.47)O3–xBi(Y0.7Fe0.3)O3 for energy-harvesting devices

Microelectronic Engineering 126 (2014) 71–78

Piezo actuator having an electrode structure for a torsional vibration mode, and rotation-type ultrasonic motor including same

Electron. Mater. Lett., Vol. 10, No. 1 (2014), pp. 223-228

Piezo Ceramics

PZT

Piezoelectric Ceramic (PZT) is a functional material that transforms mechanical pressure

into electrical signals, and electrical signals into precise vibrational energy.

At Eco DM Lab, we develop high-sensitivity, high-durability piezoelectric ceramics

to deliver solutions across medical devices, precision machinery, and sensor systems.

Engineered for miniaturization, silent performance, and precise control,

this material is recognized as a core component shaping the industries of the future.

1MHz

Thickness : 2.1mm Outer Diameter (OD) : 34mm

Inner Diameter (ID): 14.8 mm

3MHz

Thickness : 0.7mm Diameter : 12mm

Product Line

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

DM1

A sensor material with high dielectric constant and thermal stability, built for precision and durability.

Key applications

High-temperature sensor

High-reliability sensor

DM2 / DM3

Low-loss, stable vibration makes it ideal for ultrasonic cleaners and actuators.

Key applications

Ultrasonic cleaner

Ultra-precision actuator

DM4

With an ultra-high sensitivity of d₃₃ = 810, this material is tailored for precision medical diagnostic sensors.

Key applications

Advanced medical diagnostic sensor

DM5

Delivers stable performance under high-voltage conditions, versatile for industrial and medical precision control applications.

Key applications

Advanced medical diagnostic sensor

DM6

A material optimized for medical ultrasound probes, featuring ultra-precise ultrasonic response and sensitivity

Key applications

Medical ultrasound probe

Fields of application

Performance indicators

Functions

Advantages

High dielectric constant (k)

Electrical storage capacity

Improved sensitivity and precision

High mechanical q value

Vibration quality retention

High-frequency precision diagnostics enabled

High d₃₃ value

Vibration-to-electric conversion efficiency

Implementation of high-sensitivity sensors

High curie temperature

High-temperature operating stability

Enhanced adaptability to industrial and medical environments

Low tanδ (loss factor)

Energy loss minimization

Reduced heat generation for long-duration operation

Core technological competence

Custom design flexibility

Optimized for medical, precision machinery, and smart devices with diverse form and structural design options

Uniform microstructure

(1–2 μm particles)

Superior mechanical strength and durability for the production of high-reliability products

High q characteristics

(high quality factor)

Excellent resistance to thermal variation during extended use ensures stable operation without performance loss

High Kp

(high coupling coefficient)

Superior electro-mechanical energy conversion efficiency that maximizes sensor and actuator performance

Patents and publications

Piezoelectric materials of (1-x)Pb(Zr0.53Ti0.47)O3–xBi(Y0.7Fe0.3)O3 for energy-harvesting devices

Microelectronic Engineering 126 (2014) 71–78

Piezo actuator having an electrode structure for a torsional vibration mode, and rotation-type ultrasonic motor including same

Electron. Mater. Lett., Vol. 10, No. 1 (2014), pp. 223-228